In particular, Mavic and DT Swiss both developed the ultimate box-section rims in what have become the OpenPro and 415/465. With 3-cross lacing and quality Campy or Shimano low-flange hubs, standard 32 or 36 spoke wheels in the 1500-1600 gram range soon became ubiquitous, and lasted 10-25,000 miles. These wheels made the wheel mfgs NO money. With everyone selling the same wheel, it was a race to the bottom on price.

Wheel mfgs responded by making wheels with all kinds of goofy designs, and promoted them with huge marketing budgets, and flashy decals. In most cases, the result is a wheel designed to fail in 3-5 years, impossible to service, and that falls out of 'fashion' after the mfg's marketing campaign moves on to promote some new tinsel wonder.

Some fads, promoted as having some rider benefit, are really cost-cutting measures. The most prevalent of these is radial spoking, and cartridge bearings. Anybody can build a radially-spoked wheel. Even factory workers in Cambodia, paid 22 cents an hour, can build a radial wheel using cartridge bearings. They don't even need to know how to count - bearing balls, holes, or spokes!

A radially-spoked wheel, as Brandt goes to great lengths to show, is inferior in every dimension to 3-crossed lacing, but the myth of radial wheels persists, reinforced by intense marketing campaigns, in an industry addicted to unskilled labor. In particular, radial spoking creates so much force pulling away from the flange that most mfgs specifically exclude them from their hub warranty.

It is not radial spoking that creates stiff wheels, it is larger flanges, and more spokes - overwhelmingly. First by allowing for shorter spokes, 2nd because the flange flexes very little with lateral loads, and 3rd, because the spoke angles are necessarily steeper/stronger. Fewer spokes can be used with deep section rims as they are much more resistant to bending, but this does nothing to prevent low-spoke count wheels breaking spokes, hubs, and pulling through rims. For mtb front wheels with disk brakes, all the caveats of rear road wheels apply.

Being 5-10% shorter for current flange sizes, and therefore less elastic, radial spokes are more likely to break, rip through the rim, and have a harsher ride. The larger the flange, the greater the difference in spoke length. A typical medium-flange hub with 32 spokes is in the 6% range. My best guess for the increased elasticity of DT's 14/17ga Revolution spokes over straight 14ga is 30%, based on values reported for 16ga spokes. Taken together, this makes my new 32 spoke 2-cross front wheel with Revolution spokes about 35% 'softer' than the original 20-spoke wheel made with straight 14ga spokes.

Other myths surround rotational weight, the inferiority of J-hook spokes, the supposed superiority of straight-pull spokes, and hub-side spoke adjustments. It seems lost on people that the real reason mfgs like these technologies is because it's easier to make a machine to tighten a few spokes at a central location, than many spread out along the rim. It should also be noted that the cost of building a wheel is roughly proportional to the number of spokes, as that's where the labor cost of wheel building is.

As for the classic J-hook spokes, especially with double-butted spokes having heavy 14 gauge ends, the alleged excessive stretching at the bend is infinitesimal, and far less than the change in length due to temperature changes. In fact, the difference caused by heating of black, vs sliver spokes on a hot summer day is probably greater than J-hook spoke stretch. The weight of those 'evil' spoke nipples? 8 grams for 32 spokes! That's less than 3 tenths of an ounce! The dirt on a road bike tire weighs more than than.

|

| IsoPulse: Engineering idiocy trumped by marketing hubris |

Physics 101 says the drive-side spokes (also true of the rotor-side spokes on a disk brake wheel) should never, ever be radially spoked, because they'll have no ability to resist the wind-up attendant with the application of torque to the hub, positive, or negative. The other reason is radial spoking weaker for any given spoke tension, and since the drive side is deeply dished, it's already at it's max tension on a properly designed wheel - typically at 175% of the non-drive side.

Using radial spoking on the drive side means all of the torque must be transferred across the hub body to the non-drive side spokes. On a conventional 3-X spoking, only 12% of the torque is transferred through the hub body, as it's elasticity is much greater than the flange and steel spokes on the drive side. Hub bodies are VERY bad at transferring torque, as their torsional rigidity is surprisingly poor.

Larger flanges resist wind-up better, keeping torque on the drive side, while larger diameter hub bodies transfer torque to the non-drive side better. For low spoke count rear wheels with small diameter hub bodies, hub fatigue may become a durability issue. For mtb rear wheels with disk brakes, both flanges should be large and use 3-X spoking.

A serious implementation flaw with Ksyrium wheels is the use of aluminum spokes. Unlike steel, aluminum has NO fatigue limit, so it will eventually fatigue to zero strength. Two of our club members had their Ksyrium wheels fail within a few weeks - one one the Death Ride, with its high speed descents.

Finally, Ksyrium wheels are said to be extra strong because they start with a very thick rim body and machine away the aluminum between the spoke beds. Yes, but that leaves a surface that acts like a pump, and creates a lot of aerodynamic drag. The bladed spokes used to compensate make for wheels that are very hard to control in heavy cross-winds - especially on high-speed descents - and bladed spokes cannot pass through conventional round flange holes, so a lot of tricks must be used to bed spokes on the hub side.

You always know you have a good engineering solution when one change makes everything else easier, better, lighter, etc. In short, with good engineering solutions, everything gets better. Instead of trade-offs, you get virtuous cycles of synergy. It should be clear by now that the Ksyrium fails this fundamental test of engineering, as many trade-offs had to be made, all of them with side-effects that are only partially mitigated by other induced engineering requirements.

Still not convinced? You're thinking that factory-built wheels are lighter, and more aerodynamic? Ksyrium wheels weigh 1485 grams, and are one of the lightest non-carbon wheels on the market. Keep this in mind as you view the weights of custom-built wheels below. Also note, many factory built wheels are only sold in pairs, so expect to end up knee deep in extra front wheels you'll never wear out - chronically buying pairs when you only need a new rear wheel.

Custom built wheels can be rebuilt many times, as usually the braking surface on the rim is the limiting factor on their life. They also typically have loose ball bearings, which are superior at any price point to cartridge bearings. If you do buy hubs with cartridge bearings, make sure you can still get those bearings 20 or 30 years from now. If not, the hubs will be worthless. On the other hand, if loose ball hub cups get pitted, the hub is worthless, whereas a cartridge bearing comprises both cup and cone, so replacing the cartridge replaces all bearing components.

Chris King, and DT Swiss use cartridge bearings. Shimano and Campy use loose balls, which can be easily purchased, and upgraded to ceramic balls if desired. If you like a hub with cartridge bearings, and they aren't a common industrial bearing, buy a half-dozen extra, and store them in Moble 1 Oil (with seal conditioner). By the time you use the last one you'll appreciate having paid 20% of its 2025 price.

If you break a Ksyrium spoke on an event ride, good luck finding anyone who can help you replace it. You're done for the day. Custom built wheels using standard J-hook spokes are usually on hand at event rides. No problem finishing the ride.

There are some other interesting options available on most custom builds. One I am interested in is radially spoking the non-drive side spokes. These spokes have very low tensions, as normal tensions would pull a dished wheel out of dish. Radial spokes are shorter, so less elastic, which may create a wheel that responds more uniformly under load when used on the non-drive side.

Another approach is to use 14/15 double-butted spokes on the drive side, and DT Revolution 14/17 spokes on the non-drive side. In both cases you're trying to get the spokes, at dramatically different tensions, to respond as equally as possible to side loads. For me, at 190 lbs, and capable of torquing out 1,000+ watts, this seems like the better option. Also, the less elastic drive-side spokes minimize wind-up, so less torque will be transferred through the aluminum hub body, reducing fatiguing stresses. The two strategies can be combined for maximum effect.

A single unbutted 14ga spoke will not fail under 700+ lbs of load, is generally about 10% stronger than a 14/15 butted spoke, will fail at the J-hook bend, and has at least 20% less elasticity than 14/15 butted spokes. By contrast, DT's 14/15 butted spokes will stretch over 6mm without breaking (testing was stopped at 6mm of strain), mostly in the thin, center section. I don't have data for DT's Revolution spokes, but expect this general trend would continue. There is much anecdotal evidence that this elasticity makes for very tough, resilient wheels. It also makes for a more supple ride.

These builds were done at Excel Sports, and WheelBuilder. I encourage you to play, dream, and then take the plunge. In the case of Excel, you can send the hub back and have another wheel built on it as many times as you like. Bike shops will typically NOT reuse old spokes, but provided you keep the spokes in the same hub holes - so you don't bend them in new ways - reusing spokes is completely safe within reason. Rear, drive-side spokes will fatigue first, so worth checking the nipples to see if any have been taken up excessively.

As most of you know by now, I bought my wheels from Colorado Cyclist. They are an excellent shop, but don't have item-specific weights on their web site. I had my wheels built with DT Revolution spokes, and except for some rear wheel flex in left-hand turns under power, swear by them. They weigh about half as much as straight 14ga spokes. Chose silver nipples, as the colors all fade to silver in 2-3 years and look crappy in the meantime.

Build #1: Classic Campy Record hubs with OpenPro wheel weighing 1,500 grams for less than $550. This will support Campy's 9,10 and 11-speed gearing and for any rider under 200 lbs, should last 25,000 miles. Since the life of a wheel is limited by braking surface wear, go with the OpenPro Ceramic rims for ~ 100,000 mile life. 12 yrs at 8K/yr, or 20 yrs at 5k/yr. Repack and replace the bearing balls every fall, and repack each spring.

Build #2: Chris King R45 hub and OpenPro rim with radially spoked non-drive side rear wheel. Weighs 45 grams less than the Ksyrium SL and is $690. Buy extra bearings when you buy the wheels. Go with Open Pro Ceramic for longer life. 1440 grams

Build #3: Ultra-light 65mm aero wheel build. 1450 grams. Blows away SRAM's S60 60mm aero wheel at 1850 grams.

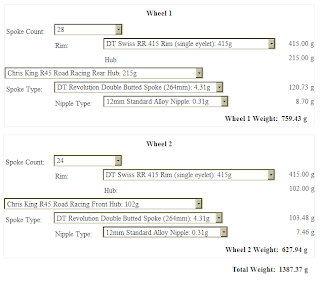

Build #4: Lightweight metal climber's wheel using DT Swiss's RR415 single-eyelet rims for riders under 165 lbs. For riders under 135 lbs, save 25 grams by using 24 spokes front and back. 1390 grams

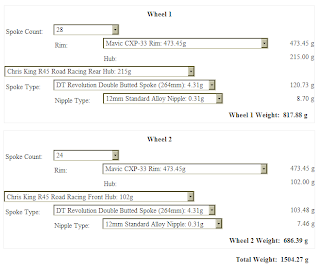

Build #5: Semi-aero metal wheel for riders under 175 lbs featuring Mavic's CXP-33 double-eyelet rim. With 32 spokes, a real Clydesdale special, up to 225 lbs, and with Shimano DuraAce with 36 spokes in back to 250+ pounds. 1504 grams

Build #6: Iowa Hill Special. Ultra-light climber's sew-up wheel featuring Enve Composites 1.25 tubular rims. Using Zipp hubs will shave 41 grams and get you under 1 kg. 1020 grams

Build #7: Metal aero wheel featuring DT Swiss RR 585 rim in front and CXP-33 in back. 1650 grams

No comments:

Post a Comment