Having shrunk my handlebar stem from 120mm to 100mm to account for me shrinking with age (EEeeeek!) I needed to shorten and re-thread my shifter and brake cables and housing. Not such a big deal except I have aerobars, a headlight, and a Garmin to accommodate, and it makes for a very busy cockpit to put together.

I also wanted to thoroughly clean the frame, and polish it, which is a lot easier, and really only possible on my bike with the crank pulled. I also pulled off the derailleurs so the frame was completely unencumbered, before threading new shifter cables; a seasonal maintenance thing for me as I'm very active on the gears when riding.

Having pulled the crank I decided to thoroughly clean the chainrings by soaking them in a metal pan, along with the derailleurs, in a solution of Dawn dish soap and distilled water. Placing the pan on my solid-surface stove on a LO setting to get it to a simmer worked great, but I did remove the two plastic pulley-wheels from the back derailleur first. This is now the best way I know of to clean derailleurs. Tremendous results! I applied T-9 BoeShield, a waxy lube invented by Boeing for cleaning aluminum aircraft parts. (I used pure Teflon grease on the Ceramic Bushing and an ABEC 7 rollerblade oil on the bearing called "Bones Speed Cream" when reassembling the rear derailleur)

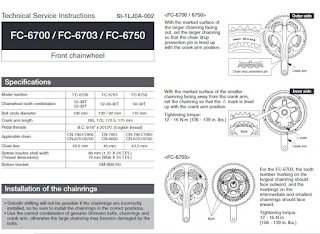

This still left the assembly of the crank to be done, and after a few days of being torn down and set aside I had to figure out exactly how it went back together. I Googled for the official Shimano R&R instructions and found most of that targeted at the 2-ring 6700, which left some questions in my mind. Online videos were also not very helpful, but I did find one Blog that was helpful (linked at the bottom here), but even that left some question marks about how to tear down the chainring assembly, vs R&R of the whole crank assembly.

This YouTube video is pretty good at showing the details of how to R&R the crankset, with a few caveats.

1st, hammers and bearings don't mix. Hammering on a bearing peens the balls into the races and ruins the bearings. Plastic and rubber mallets get metal bits embedded in them over time,so hammering any finished surface with them is a BAD idea. If you must risk peening your bearings or breaking them by using a hammer (a VERY crappy idea) put a clean cloth or bit of inner-tube over the surface you are fixing to bash. I've never yet had to do this and think it's a really horrible idea, but hey, it's your pocketbook.

2nd, the Shimano bottom brackets are all sealed bearing systems, so the lube you put on the spindle is purely for sealing out moisture - which is impossible - and water displacement. The volume of air inside your bike's tubes holds more air when that air is dense(cold) than when thin(hot), so everyday heating and cooling is going to force the frame to "breathe", and if that air has moisture in it, which it will, when it cools beyond the dew-point you will get water inside your frame tubes. Bike mfgs know this, that's why they put a small hole in the bottom of the bottom bracket shell. This doesn't mean grease can't protect your bits from rusting by DISPLACING water, but that's a different requirement than lubricating a bearing or bushing.

3rd, when loosening ANYTHING with a torque specification, just as when tightening it, use a torque sequence, or make one up to follow, and loosen the bolts bit by bit. When R&R-ing the chainrings for example, don't go around. Instead, hop back and forth to opposite sides and loosen a little bit at a time.

4th, go easy with the little plastic thing-a-magiggy that sets the bearing pre-load. With any sealed bearing the bearing is just slid into position on a tube. As long as that position is maintained it's going to work properly. This in contrast to ball bearings where the cups and cones are ground at ~ 45 degree angle so the pre-load has a big impact on how the balls engage the encasing surfaces. After the 1st ride, recheck the preload and snug it up if it needs it. As with all bearings, a little loose is better than too tight.

Finally, the polymer tool that comes with Shimano bottom brackets, shown below, will never mark up your BB, so I would RX that over the metal toothed steel wrench seen in the video. It works best with the "socket" style BB tool below that completely covers it. Put the bike on its side like you're branding a calf so you can push against the BB and you can get is as tight as you need it without slipping.

Chainring Tear-down:

I couldn't find a good video of how to tear down a Hollowtech triple crank, and can't find my tripod to make one myself (yet), but did take some helpful still photos. Note, the comments are on the bottom of the photos. These mostly deal with how to properly align the chainrings before bolting them together.

The 6703 uses Torx-30, not 5mm hex head nuts, but otherwise the same.

When working with a triple like the 6703, take it apart from the smallest to the largest ring, BUT, when reassembling it, put the inner TWO rings together as a sub-assembly and then bolt that to the spider and outer ring. The torque needed to break the bolts free can then be managed by holding onto the crank arm. Trust me. There a LOT of ways to get this wrong.

Proper alignment of the outer ring is easy, the chain-drop pin must be centered over the crank arm. If it wasn't, it couldn't keep your chain from falling down into that nasty crack.

Note there are two registration marks indicating alignment here. A "pip" on the small ring and a ^ mark on the middle ring. Make CERTAIN those are pointing right at the crank arm.

Here you can see the back of the chain-drop pin, pip, and ^ all lined up, pointing at the crank arm.

Shimano's official docs make a big deal out of where the stamping are on the chainrings. They're on the outside for the large chainring so Shimano can advertise, but are facing inwards on the middle and smallest chainring - FWIW. Use the registration marks for alignment. The stampings move around all the time, so OK for tooth info, but not for alignment.

UPDATE: 10/30/2019

As advised, I used just a little grease on the chainring bolts when tightening them up to get a better feel for the torque. After 6-7 months though I started to get a creaking in the bike. Part of that was the headset needed to be cleaned and reinstalled, but most of it was due to the chainring bolts needing tightening. My suggestion is therefore that you use a little LockTite on the chainring bolts so they don't work their way loose.

Lower right corner points out the chainring stampings as outside on the large ring and inside on the two smaller rings, just in case it isn't obvious.

These are the ring and spacer parts referenced in the info box next to #6 in the Shimano doc below. The ring goes on 1st and engages a raised plastic ring on the face of the spacer. The smaller side of the spacer goes towards the BB and the larger diameter side towards the removable crank arm.

There is a plastic last-ditch retention dohicky (stopper plate; no midnight oil burned naming that!) that engages the hole in the crank seen in the photo below. The slotted end goes to the outside and the hole goes to the inside. If you can't get this part to seat you have the two crank arms parallel instead of offset 180 degrees.

I'm tempted to scoff at this "lawyer plate", meant to keep Shimano from getting sued, probably for the 2nd time, but actually it's pretty clever and might save you from injury if those pinch bolts both failed, or your brother-in-law isn't quite the mechanic he assured you he was. Plus, it gives you a better indication of how tight those pinch bolts are getting. If you aren't sure, use a torque wrench.

BEFORE tightening the removable crankarm's pinch bolts, BEFORE, set the preload so there is no play in the crank, especially at the ends of the arms. Only when the pre-load is set should you begin locking the crankarm into place by torquing the pinch bolts down, little-by-little, going back and forth between them. Make very sure those pinch bolts and their engagement threads are absolutely clean, and lightly oiled, so you get a good feel or torque reading.

When in doubt, torque it out!

...

No comments:

Post a Comment